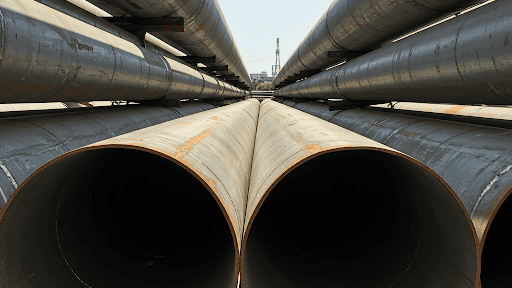

EonCoat® anti-corrosion surface treatment technology for industrial carbon steel assets

Economically sustainable

Less preparation, faster application and a longer product life expectancy maximises recoat times and economic benefits

Environmentally friendly

The inorganic formulation of the EonCoat® treatment is more environmentally sustainable relative to traditional coatings

Safer to use

The non-toxic nature of EonCoat® is safer on human resources applying the product, for example in confined work spaces

EonCoat® offers a comprehensive two-part system that delivers dual layers of protection for your carbon steel assets.

EonCoat® is unlike a conventional barrier coating which sits over steel. The patented EonCoat® corrosion prevention technology offers two layers of protection in a single coating. Upon application, the surface undergoes a chemical reaction, resulting in the formation of an alloy layer and a protective ceramic layer. The alloy layer is the first layer of protection against corrosion, formed when EonCoat is sprayed to carbon steel and chemically changes the steel surface to an amorphous magnesium iron phosphate. The second ceramic coating layer has a reservoir of phosphate that feeds this alloy layer over time providing effective anti-corrosion properties for carbon steel.

EonCoat® Australia is committed to supporting industry with more sustainable and environmentally focused, corrosion management technologies, which are effective in preventing corrosion. In addition to the clear environmental benefits, a key advantage of the EonCoat® innovation is in delivering improved efficiency resulting in decreased shutdown and turnaround time

Our Product Range

Corrosion Protection coating is EonCoat®’s flagship coating, suitable for all carbon steel applications, with a broad temp rating of 10°C to 48.8°C

EonCoat’s CUI (Corrosion under insulation) Coating is rated from -160°C up to 450°C and suitable for insulated pipelines and tanks

Best suited to carbon steel assets which requires welding, this coating can withstand welding temperatures of up to 600°

Case Studies